South Korean auto giant Hyundai is planning to begin using humanoid robots at its US manufacturing plant in Georgia, as part of a larger push into the physical artificial intelligence market.

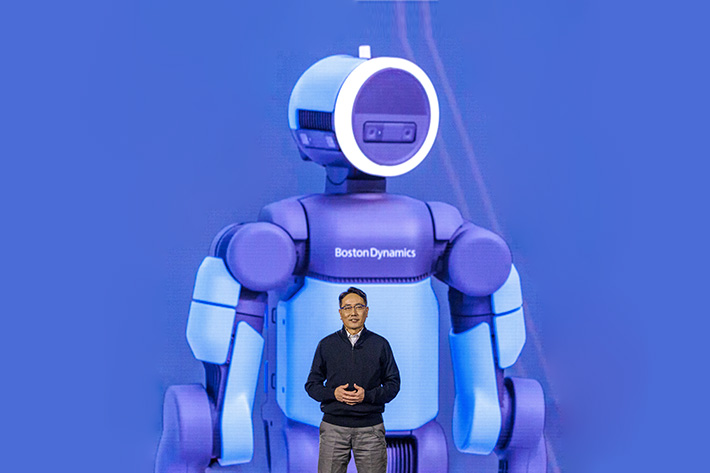

The carmaker will deploy the production version of the Atlas humanoid robot, developed by its unit Boston Dynamics, starting in 2028, the company said at the Consumer Electronics Show in Las Vegas on Monday.

Hyundai did not disclose the cost of the robots, but said in a statement that it aims to roll out adoption across all of its manufacturing sites as part of a push into “physical AI.”

Also on AF: Chip Prices Fly Amid AI Boom, Samsung ‘to Flag Huge Profit Jump’

Physical artificial intelligence refers to AI systems embedded in hardware that collect real-world data and make autonomous decisions, spanning areas such as robotics, smart factories and autonomous driving.

Hyundai expects humanoid robots to become the largest segment of the market. The automaker said it plans to build a factory capable of manufacturing 30,000 robot units annually by 2028.

Some automakers also see an overlap between autonomous driving and robotics, because similar sensing, perception and decision-making technologies underpin both aspects of the emerging field of embodied AI.

The Atlas robots will initially carry out parts sequencing tasks from 2028, with applications expanding gradually as safety and quality benefits are validated, it said.

By 2030, Hyundai said Atlas robots were expected to move into component assembly with a longer-term plan to take on tasks involving heavy loads, repetitive motions and complex operations across production sites.

Job loss concerns

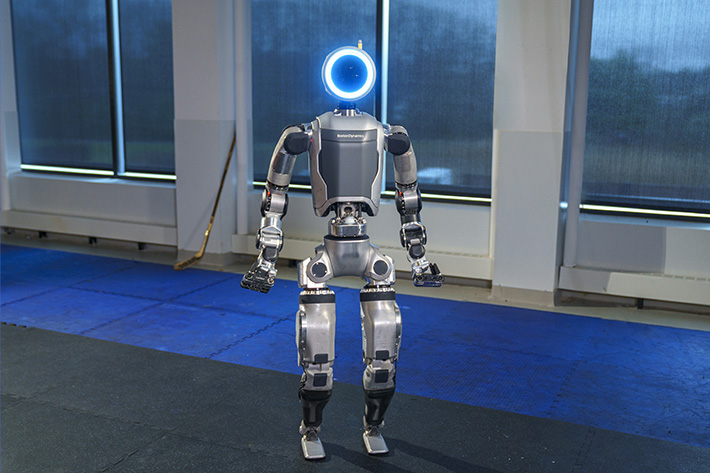

The production version of the Atlas humanoid robot, unveiled on Monday, is designed to reduce physical strain on workers by taking on higher-risk and repetitive tasks, laying the groundwork for broader commercial use in industrial settings, Hyundai said.

But the company faces concerns that the use of these robots could come at the cost of factory worker jobs. Last year, the labour union at Hyundai Motor’s affiliate Kia Corp called for a body to be set up to address potential labour rights issues in preparation for the AI era, as workers raised fears about their jobs because of expanding automation.

Speaking at CES on Monday, Hyundai Motor’s vice chair Jaehoon Chang said that the company understands concerns about job losses, but people will be needed to maintain and train the robots, and additional personnel will be required.

Atlas features human-scale hands with tactile sensing and has the ability to lift up to 50 kilograms (110 pounds), according to Hyundai.

The robot can operate autonomously and is designed to function in industrial environments ranging from minus 20 degrees Celsius to 40 degrees Celsius.

Hyundai said it is accelerating development in this area through partnerships with global AI leaders, including a collaboration with Nvidia and Google, aimed at improving safety, efficiency and real-world deployment.

- Reuters, with additional editing by Vishakha Saxena

Also read:

Continuing AI Demand Lifts Asian Stocks to Five-Year Highs

Korea, China Shares Post Highest Gains in Years Amid AI Frenzy

Shares of Korean Battery Firms Sink Amid Global EV Uncertainty

Seoul Accuses Ex-Samsung Staff of Leaking DRAM Tech to China

How A Visa Loophole Landed Korean Workers In Trouble

China Claims Win in First Ever Race Between Humans And Robots